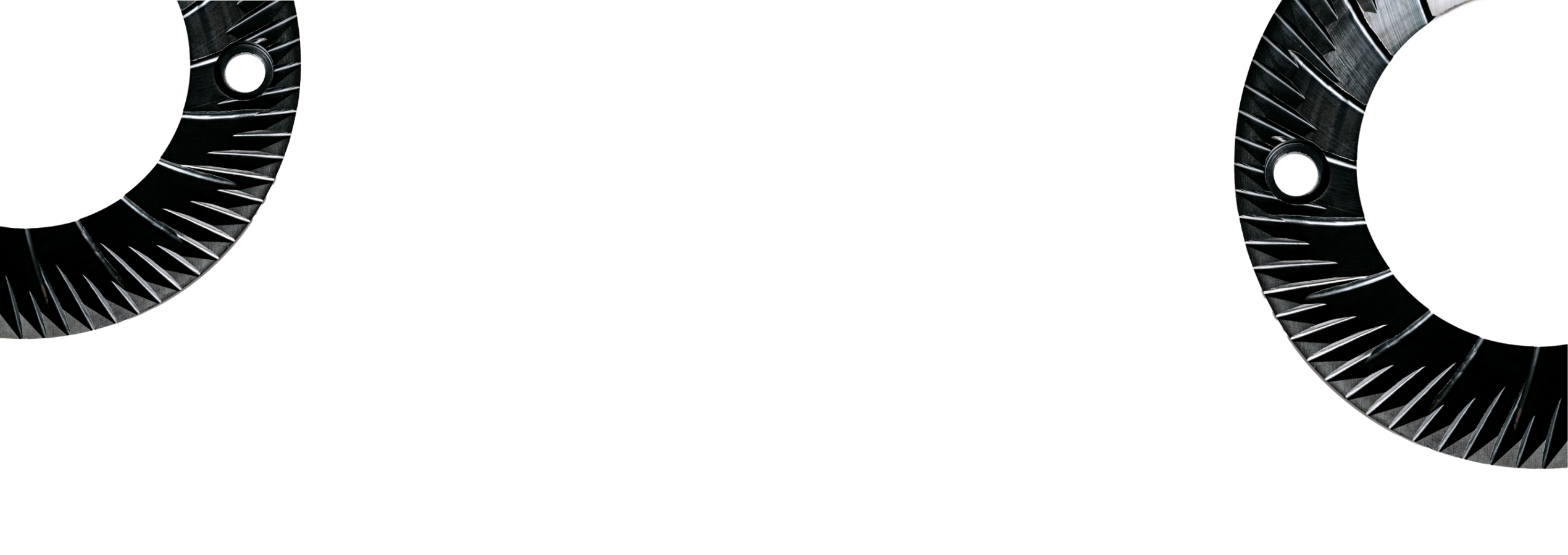

Our supply chain is 80 percent in-house: one of Fiorenzato’s greatest sources of pride. This means greater control over each individual component and every single step in assembly; easier verification of solutions proposed by the R&D department with specific tests; greater sustainability, avoiding waste and the cost of transporting materials. All this is made possible by in-house production of burrs, making the entire process of producing professional coffee grinders leaner and more efficient.

Our supply chain,

your quality

Our burrs are made entirely using a single state-of-the-art CNC machine.

This allows the entire process to be carried out in a single step, ensuring maximum precision, uniformity and high performance for each individual burr produced.

The technology offers four essential advantages:

Absolute repeatability - each burr is identical to the next, with no variations.

Excellent quality - flawless finish and minimal tolerances.

Consistency over time - reliable performance, day after day.

Optimised production time - maximum efficiency, no waste.

Our certifications

Fiorenzato constantly invests in the value and safety of its products with electronic and chemical tests and inspections. Rigorous quality control allows the company to export to the United States, Canada, South Korea, Russia and Brazil